Understanding Solder Burn on Adjustable Bed Bases

Posted by Peter Anania on 31st Jul 2019

Welding is an essential manufacturing process, particularly in the construction of adjustable bed bases, where durability and precision are paramount. One phenomenon that often causes concern among consumers is the appearance of what's known as a "solder burn" around welded joints. Despite its somewhat alarming name, solder burn is a common, perfectly normal occurrence in the welding process and is not indicative of a defective product. In this blog, we'll demystify solder burn, explaining what it is, why it occurs, and why it's nothing to worry about.

What is Solder Burn?

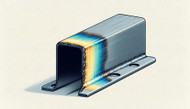

Solder burn, often referred to as weld discoloration or heat tint, is a visual manifestation that appears on the metal surrounding a welded joint. It's characterized by a rainbow-like or sometimes dark discoloration. This phenomenon is a direct result of the high temperatures used during the welding process, which can cause the metal's surface to oxidize at different rates, leading to a variety of colors based on the temperature reached.

Why Does it Occur?

During the welding of adjustable bed bases, intense heat is applied to fuse metal components together, creating a durable joint. The temperatures can reach upwards of several thousand degrees Celsius, depending on the metal being welded. This heat causes the surrounding air to react with the metal, forming an oxide layer. The specific colors of the solder burn—ranging from straw yellow to deep blue or even purple—are indicative of the maximum temperature the metal reached during welding.

Solder Burn vs. Rust: Understanding the Difference

At first glance, the discoloration caused by solder burn may be mistaken for rust, especially by those unfamiliar with welding and metalwork. However, there are distinct differences that can help differentiate between the two. Solder burn typically presents as a uniform, smooth coloration around the weld area, resulting from the controlled application of heat. In contrast, rust is the result of uncontrolled oxidation over time, often appearing in patches and with a texture that can feel rough or flaky.

Rust formation is a gradual process that typically occurs in the presence of moisture and oxygen over extended periods. Its appearance is seldom uniform, making it visually distinct from the uniform hues of solder burn. Understanding this difference is crucial in recognizing that the discoloration around welded joints on adjustable bed bases is a sign of the welding process, not a defect or deterioration.

The Bottom Line: Warranty Coverage and Peace of Mind

When you notice solder burn on the welded joints of your adjustable bed base, there's no need for alarm. This phenomenon is a normal part of the welding process and does not affect the functionality or longevity of the product. It's a testament to the high temperatures and precision involved in ensuring your bed base is strong and durable.

Moreover, it's important for consumers to know that the frame of an adjustable bed base is covered under warranty for the full 10-year period. This comprehensive coverage ensures that any potential issues, albeit unlikely related to solder burn, are fully addressed by the manufacturer. Therefore, there is absolutely no need to worry about the appearance of solder burn affecting your bed base's performance or durability.

In summary, solder burn is a harmless byproduct of the welding process, indicative of the careful work that goes into constructing durable and reliable adjustable bed bases. With the reassurance of a full 10-year warranty coverage, consumers can rest easy knowing that their investment is protected, focusing instead on the comfort and versatility their adjustable bed base provides.